Warehouse Lighting Design

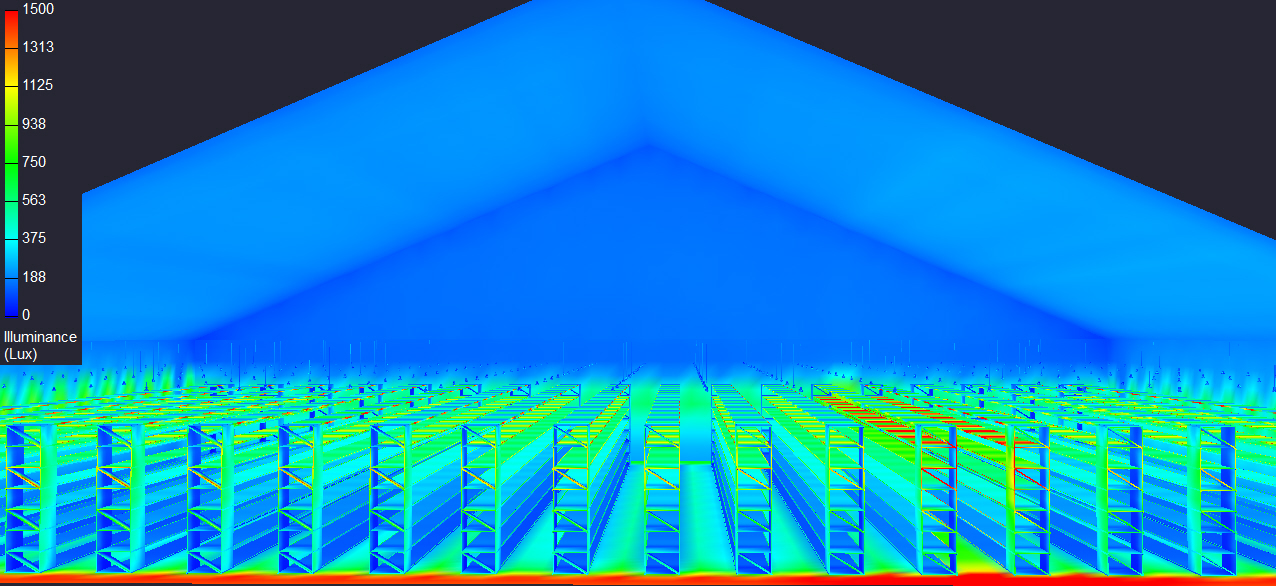

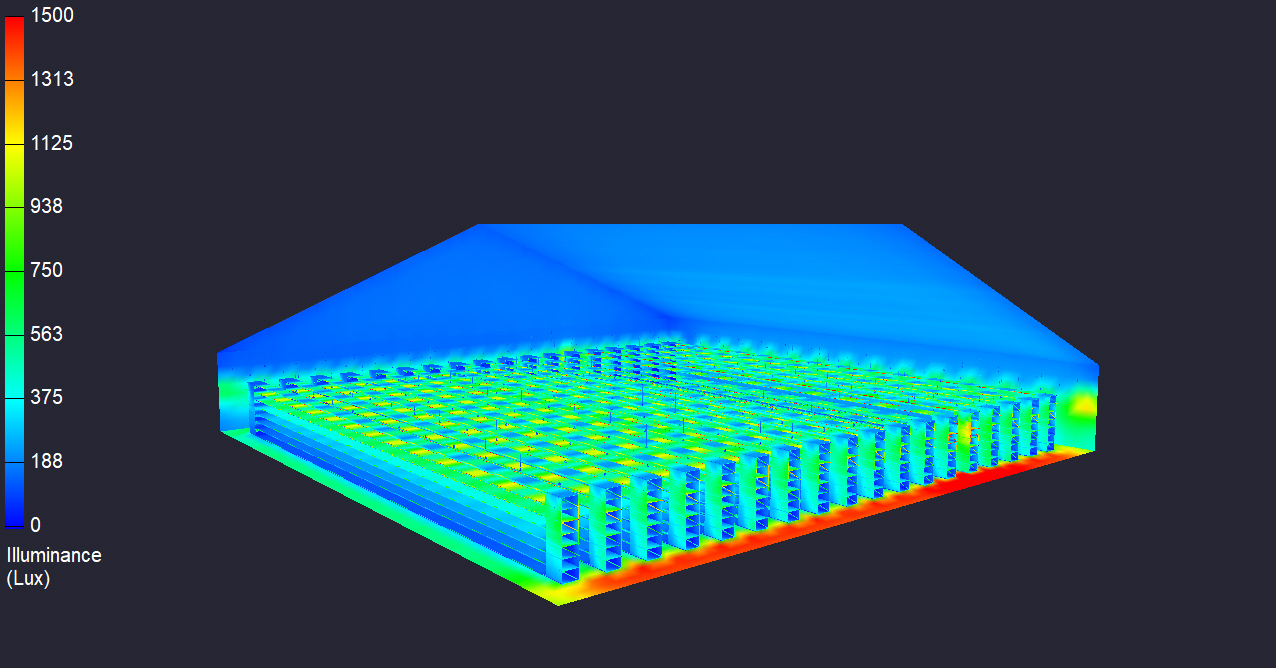

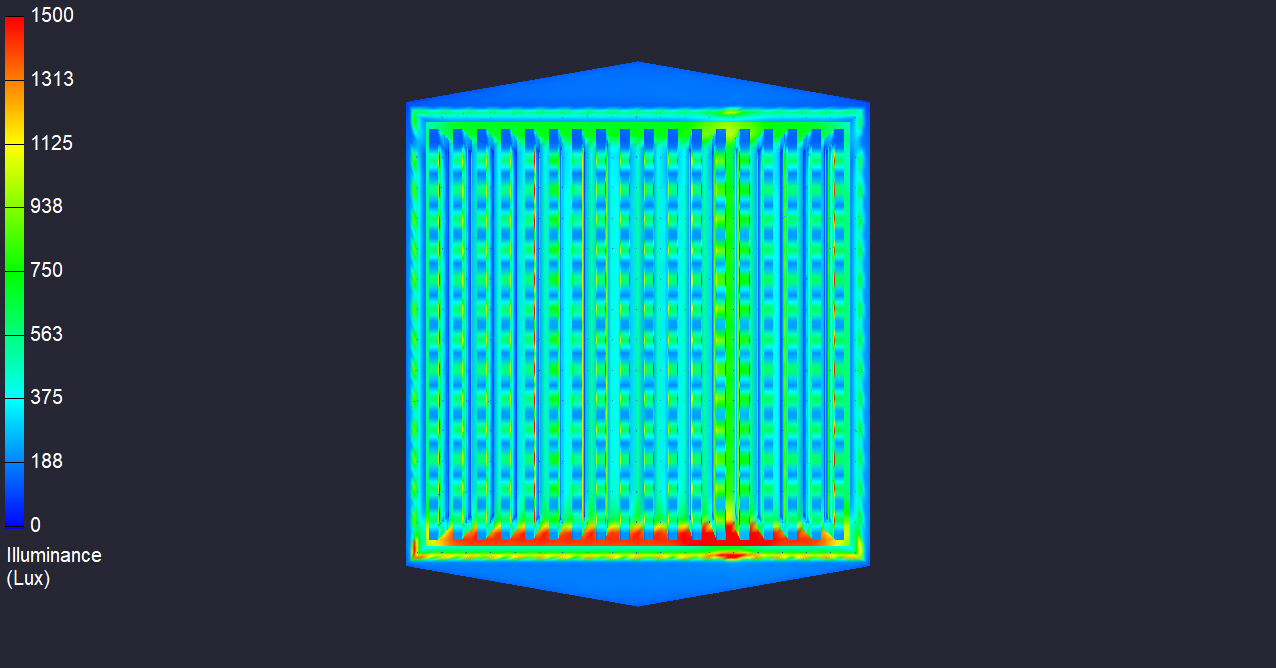

Warehouses mostly have high ceilings and elevated shelves to store materials. The floor area is mostly the aisle area between the racks. The vertical lux level on the rack is critical to see and read the label of the stored items on the high-rise racks. Also, for the people and for the forklift drivers the horizontal lux level on the aisle floor is to be calculated.

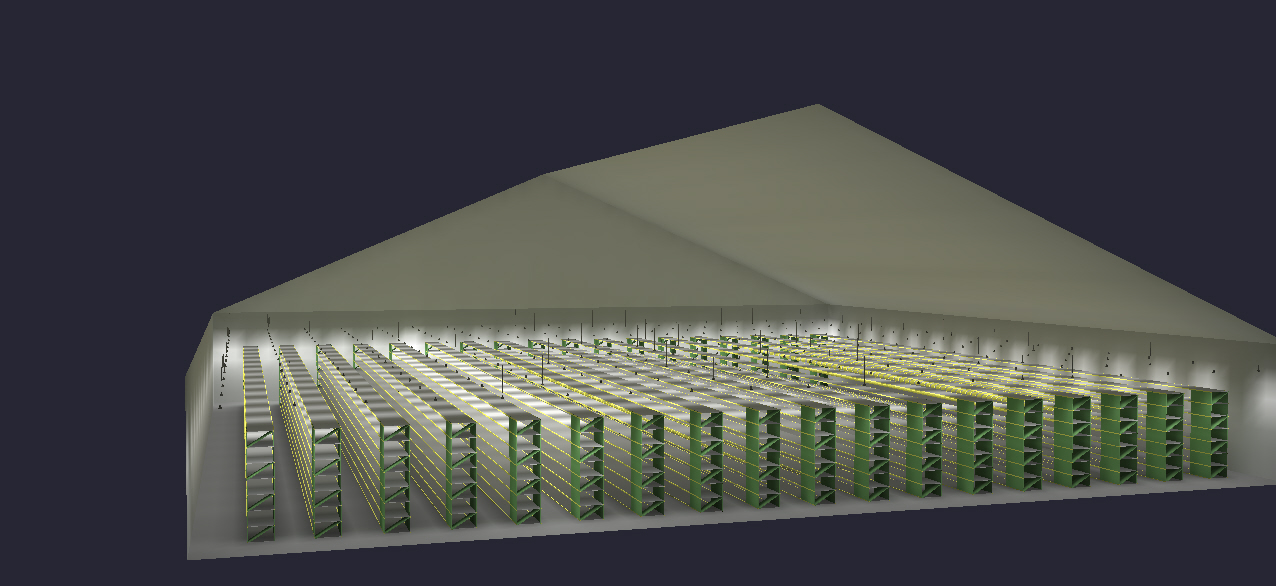

In order to arrange the lighting layout properly as related to the functional requirements of different areas in the warehouse, the racking layout should be provided to the designer.

Luminaires are laid out in the aisle area between racks with appropriate optics so that it provides sufficient vertical illumination on racks as well as horizontal on the aisle floor. Also, goods receiving and despatching areas need lighting in the same line as offices to read and process documentation.

Storage and later material picking were the most important tasks in warehouses for many years. But recent developments in information technology have brought advanced tasks like barcoding, shrink wrapping, RFID tagging of containers and boxes and material for automatic placement and picking using Roberts and other automated facilities. So, these tasks are to be kept in mind while designing lighting. Lighting should be safe enough for the staff circulating among the high-rise racks and huge storage areas.

Because of high-rise ceilings, the luminaires used should have a long lifetime and minimum maintenance required.

Warehouses can be designed with daylight access to minimize energy usage. Depending on the availability of daylight the luminaire outputs can be controlled by dimming.

Warehouse Lux level requirements as in EN 12464-1:2011 (E) are as follows:

EN 12464-1:2011 (E)

Table 5.4 — General areas inside buildings – Storerooms, cold stores

| Ref. no. | Type of area, task or activity | Ēm lx | UGRL | Uo | Ra | Specific requirements |

|---|---|---|---|---|---|---|

| 5.4.1 | Store and stockrooms | 100 | 25 | 0.4 | 60 | 200 lux if continuously occupied |

| 5.4.2 | Despatch, Packing, handling areas | 300 | 25 | 0.6 | 60 |

Table 5.5 — General areas inside buildings – Storage rack areas

| Ref. no. | Type of area, task or activity | Ēm lx | UGRL | Uo | Ra | Specific requirements |

|---|---|---|---|---|---|---|

| 5.5.1 | Gangways unmanned | 20 | 0.4 | 40 | ||

| 5.5.2 | Gangways manned | 150 | 22 | 0.4 | 60 | |

| 5.5.3 | Control Stations | 150 | 22 | 0.6 | 80 | |

| 5.5.4 | Storage Rack Face | 200 | 0.4 | 60 | Vertical illuminance, portable lighting may be used. |

CIBSE Guidelines CIBSE – Chartered Institution of Building Services Engineers Warehouse Lighting.

Warehouse Type Standard Lux Glare Index Notes Loading Bay 150 – Avoid glare to forklifts/drivers Working Stores 200 25 Large Item Storage 100 25 Local lightings may be required Small Item Storage 300 25 Local lighting may be required Trade Counter/Desk 300-500 22 Avoid glare on PC/Laptop screens Storage of items where ID requires the limited perception of detail 100 25 Local lightings may be required Storage of items where ID requires the perception of detail 150-200 25 Lighting vertical surfaces is important.

Obstacles are likely. If the area is continuously occupied increase to 200- 300Lux. Avoiding Glare Automated High Rack Stores gangway 20 – Supplementary lighting required for maintenance Automated High Rack Stores control station 200 – Avoid glare to the operator. Local lighting to be considered. Packing and Despatch 300 25 Cold Stores 300 – Cold and wet conditions likely. Care to be taken on entrance and exits.